Concrete Cancer: How to Spot Spalling Before It’s Too Late

A facility manager once ignored a hairline crack in a loading dock. By the time the surface broke away in chunks, exposing rusted steel underneath, the damage had already reached deep into the slab. That repair ended up requiring full slab replacement, drainage corrections, and structural reinforcement—none of which would have been necessary if the early signs were recognized and addressed.

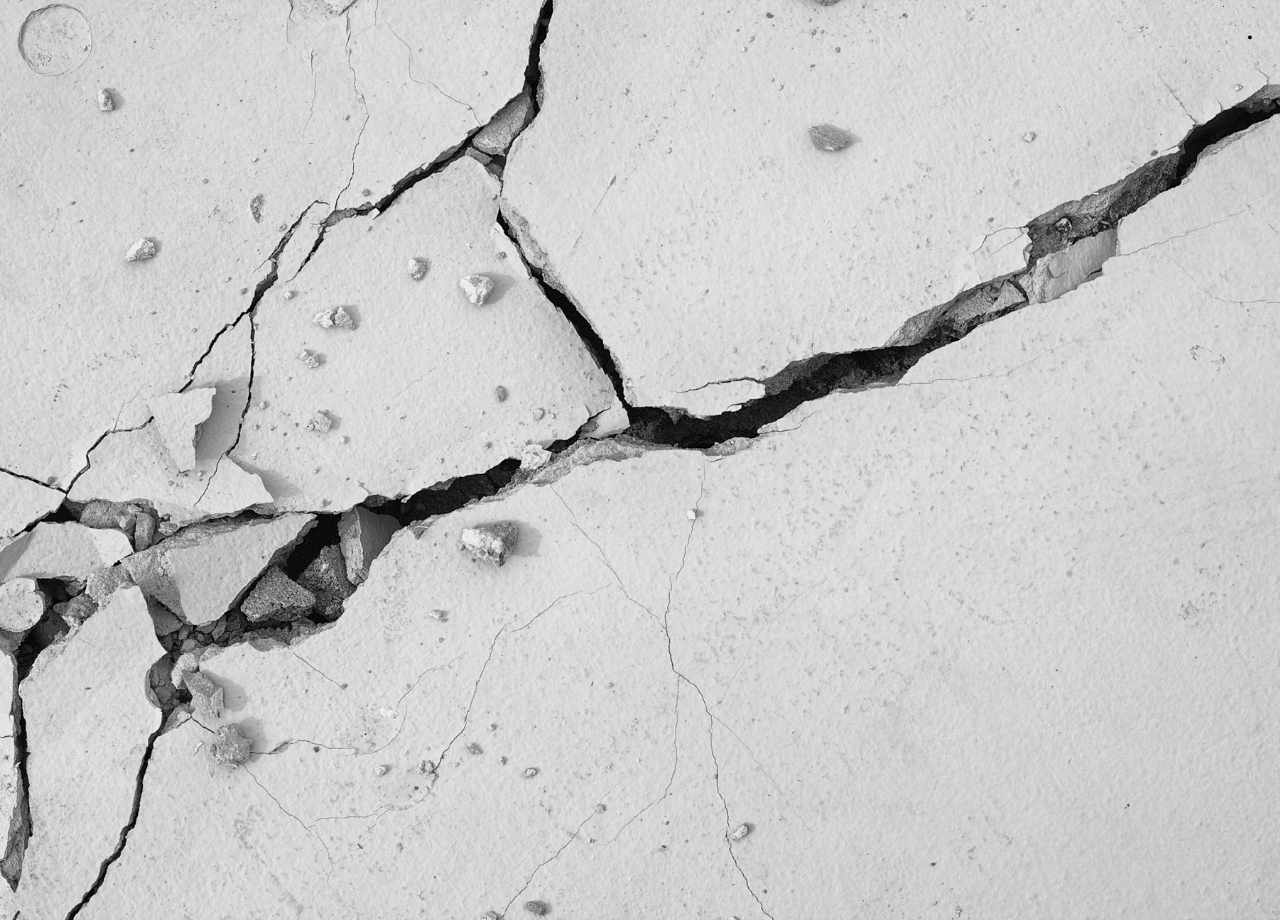

Concrete cancer, more technically known as spalling, starts small. A flake here, a blister there. The surface might pop or crack slightly. It doesn’t look serious at first glance, but beneath those signs lies a bigger issue—moisture has reached the steel reinforcement, causing it to corrode and expand, breaking the concrete from the inside out.

Rust Doesn’t Sleep

Steel reinforcement reacts aggressively to moisture and air. Once rust starts forming on rebar, it swells. That expansion puts internal pressure on the surrounding concrete. With nowhere to go, the concrete surface starts to lift and crack. The term “cancer” is apt—it spreads, it weakens, and once it takes hold, repair becomes exponentially more expensive.

Early signs are often dismissed. Small bubbles in painted surfaces, faint cracks radiating from corners, or small fragments breaking loose. These symptoms tend to show up on exposed slabs, balconies, walkways, basement walls, or parking decks—anywhere concrete is exposed to moisture and temperature swings.

How Damage Starts

Spalling typically begins when poor waterproofing, low-quality concrete, or movement in the structure allows water to penetrate. Once inside, it attacks the rebar. Freeze-thaw cycles, road salts, and even minor leaks from nearby pipes can accelerate the damage.

Airborne chlorides, especially in coastal or industrial areas, also eat into the concrete. Over time, the alkalinity in the concrete—which helps protect steel—gets neutralized. Once the pH drops low enough, corrosion speeds up.

This process can begin years before cracks are visible. By the time rust stains bleed through paint or chunks start falling off, the damage often extends several inches deep.

Where to Look First

Flat surfaces that collect water are usually the first to fail. Roof decks, stair treads, suspended slabs, and landings should be checked regularly. Edge conditions—where vertical and horizontal surfaces meet—are another common starting point. Parapets, balcony edges, and junctions between walls and floors often show signs before open spans.

Basements with high humidity or poor drainage can also develop internal spalling on walls or ceilings. Even though not exposed to rain directly, water vapor and poor airflow can trigger the same corrosion process over time.

Hairline cracks around post-tension anchors, exposed rebar near expansion joints, or old repairs that are lifting or discolored are all warning flags.

What You’ll See

Surface bubbling, lifting paint, or concrete breaking off in flakes are common. Rust streaks running down walls or discoloration in random patterns often trace back to buried steel that’s expanding. Look closely—what seems like a small area of damage often connects to a larger, hidden pocket of corrosion.

Hollow-sounding patches when tapped, or areas that feel soft under pressure, may indicate underlying delamination. Thermal imaging or sounding hammers can help identify those spots, but trained eyes usually notice long before that’s needed.

Don’t rely on obvious cracks alone. Subtle changes in texture, unevenness, or recurring moisture at the same spot should raise concern.

Small Repairs Don’t Stay Small

Trying to patch spalling without addressing the cause is a short-term fix. The concrete might look better for a few months, but if the rusted rebar isn’t treated and moisture still gets in, the surface will break down again—and usually worse than before.

Grinding away the loose material, treating the steel, and using high-quality repair mortar is just the start. If drainage, waterproofing, or structural stress isn’t corrected, new damage will form. Repeated patch jobs become a sign of deeper trouble.

One maintenance director tried three different patch products on a parking deck over two years. None of them held up. Once a full assessment was done, they found multiple points where water was entering through cracked expansion joints. By then, the spalling repair cost had tripled compared to the original estimate—turning a minor surface job into a major structural intervention.

Ignoring root causes almost always inflates cost. Surface patching might run a few hundred dollars. Full-depth slab repairs, structural remediation, and safety upgrades can easily move into the tens of thousands, especially if the damage has spread.

Warning Signs Are Easy to Miss

The early stages of concrete cancer don’t always show up where expected. An overhead beam might start spalling not from surface water, but from condensation from HVAC lines. A garage column could deteriorate from de-icing salts tracked in by vehicles, not rain. Even landscaping nearby—trees, irrigation, mulch—can affect concrete walls by retaining moisture.

If the surface seems to be flaking near a drain or along a joint, chances are the moisture problem is more widespread than just the visible spot. Likewise, staining around anchors, bolts, or fixtures can mean moisture is tracking through or behind the structure.

One commercial property had ongoing leaks in a stairwell. Each time, patching fixed the wall but not the source. Eventually, the issue traced back to a blocked scupper drain on the roof that had overflowed repeatedly—water had been entering the wall cavity for over a year.

Regular Checks Are Worth the Time

Most spalling problems don’t happen overnight. They can take months or years to become obvious, which gives facility teams a window to act—if they’re watching for it.

Visual checks should be part of routine maintenance. Don’t just look at surfaces—check underneath cantilevers, around joints, behind pipes, under balconies. Use a flashlight. Tap suspect areas with a hammer or probe tool. If you find hollow sounds, get a deeper inspection.

Photos help track changes over time. Comparing images taken six months apart can show how fast an area is deteriorating. This is especially useful for large facilities where damage can go unnoticed due to scale or shifting teams.

Don’t Wait for Structural Risk

A common mistake is assuming that spalling is cosmetic. That might be true at first, but once steel starts expanding, the damage turns structural quickly. Entire corners of buildings have failed because spalling weakened the bond between concrete and steel. Fences, signage, or balconies can collapse without warning.

Several buildings have faced legal claims after small patches of concrete fell and struck someone. Insurance often doesn’t cover damage caused by deferred maintenance.

Addressing spalling early isn’t just about appearance—it protects safety, budget, and liability.

Waterproofing Isn’t Optional

Once repairs are made, sealing the surface against future water intrusion is critical. Waterproof coatings, membranes, and drainage upgrades are often overlooked because they aren’t visible. But they’re what keep repairs from failing again.

In one case, a high-rise apartment kept getting balcony spalls even after professional repair. The issue? The top surface had no slope, allowing water to pond near the railings. Once proper slope and a sealant were installed, the problem stopped.

Water management—gutters, flashing, caulking, sealants, and expansion joint care—makes all the difference in how long concrete lasts.

Know When to Get Help

Spalling repair isn’t always a DIY job. Shallow damage can be patched by trained staff, but deeper corrosion, widespread cracking, or delamination calls for professional assessment. Engineers may need to evaluate the extent and make recommendations. Infrared scans, core sampling, or load testing could be required for structural elements.

Some buildings hide the full damage behind finishes, coatings, or insulation. Only partial removal or probes will reveal what’s happening beneath. Don’t guess—get it inspected.

Facility leaders across industrial, healthcare, and commercial portfolios turn to National Facility Contractors to assess at-risk structures, plan water mitigation strategies, and implement long-term repair programs that protect structural integrity and reduce liability exposure.

Final Thoughts for Facility Managers

Concrete cancer can quietly eat away at the strength of a structure without drawing much attention. Spotting early signs—no matter how small—gives you a chance to act before real damage sets in. With consistent inspections, prompt repairs, and a focus on waterproofing, it’s possible to keep spalling under control and extend the life of your facility’s concrete systems.

Whether you’re managing a logistics hub, a multi-tenant commercial site, or a mission-critical facility, prevention is always more affordable than reconstruction. Taking action early not only protects your assets—it keeps people safe and operations running without interruption.